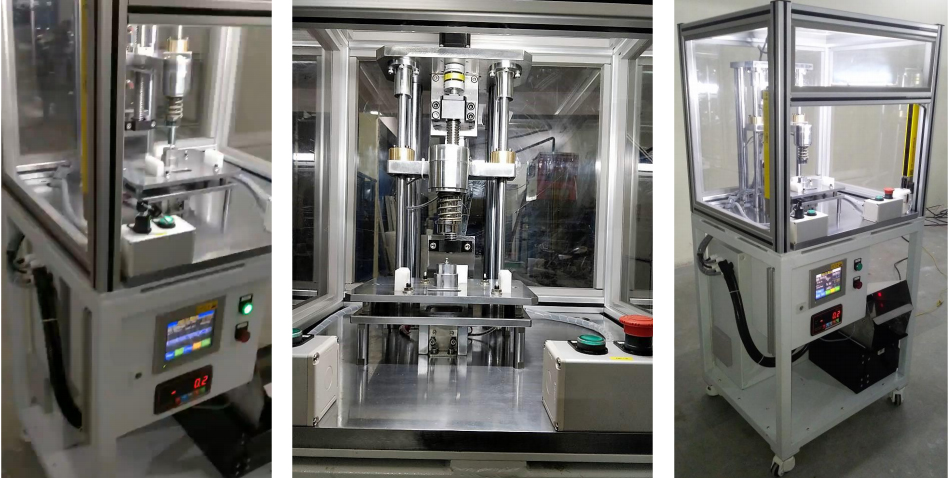

- Machine : Press Fit Machine

- Customer : Denso Manesar

- Product : mushroom part

Description

- Child Part Assy under Limited load

- Pressing mechanism done by servo ball screw mechanism

- Load Measuring by Compression Load cell

- Cycle time of machine – 6 Sec.

- Machine Name : Customized Control Panels

- Customer Name : Multiple

- Product : mushroom part

Application

- Curing oven Process control

- Paint booth Process panel

- Customized Panels

- Cycle time of machine – 6 Sec.

- Machine Name : Diode Pressing

- Customer Name : Lucas TVS Rewari

Application

- Diode Pressing

- LV Terminal Pressing

- Customized Panels

- HV Terminal Pressing

- Machine Name : Micro Arc Welding

- Customer Name : - Lucas TVS Rewari

Application

- Micro Arc Welding

- Vision Inspection

- Resistance Testing

- Machine Name : BLDC Motor Testing

- Customer Name : - Lucas TVS Rewari

Application

- This machine is designed for testing of Stator Motor Controller

- 4 No's Stations in machine

- Monitoring of Motor speed variation, direction, Current-Voltage, speed in torque applied conditions.

- Torque application by Hysteric brake motor

- 4 No's conveyors for NG Parts

- OK NG Stamping feature

- IPC Display

- Machine Name : Press Fit

- Customer Name : Denso Manesar

Application

- Child Part Assy under Limited load

- Pressing mechanism done by servo ball screw mechanism

- Load Measuring by Compression Load cell

- Cycle time of machine – 6 Sec

- Machine Name : Punch Marking Machine

- Customer Name : Denso Noida

Application

- Punch Text marking on Magneto flange

- Punch Marking Jig – Gearing mechanism

- Jig rotating by Indexing Motor

- Part clamping by Pneumatic cylinder

- HMI Display

- Part present sensor feature

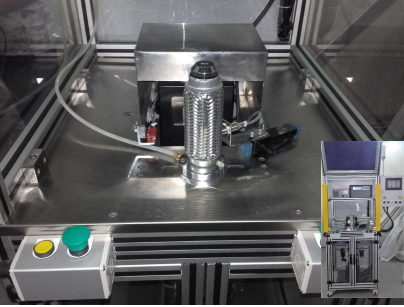

- Machine Name : Oiling Machine

- Customer Name : - Denso Noida

Application

- Controlled oil spraying on magneto

- Magneto rotated by motor gear

- PP sensor

- Sliding door during oiling

- Mist collector

- Machine Name : Wire Forming Machine

- Customer Name : Denso Noida

Application

- Armature wire forming on 800 Kg force

- Ng chute integrated

- 0.05 mm accuracy

- Harden guide

- Machine Name : Conveyor Line

- Customer Name : Minda D-Ten Bawal

Application

- 3 Linear conveyor

- 4 Rotary conveyor

- 6 Working station

- PCB Soldering line integration

- Automatic stoppers

- Machine Name : Flex Leak Testing & Marking

- Customer Name : Senior India Manesar

Application

- Leak testing unit – Ateq unit

- Marking unit – Telesis (Servo adjustment for different model.

- PP sensor – adjustment for different model

- Cycle time of machine – 6 Sec.

- Machine Name : Lever Torque Testing

- Customer Name : CKM Manesar

Application

- Two model – RHD and LHD

- 6 No's Servo slider with load cell

- Lever Wire pulling by servo motor ball screw arrangement.

- Torque (Force measurement by load cell)

- HVAC Top clamping by air cylinder

- Machine Name : Water Dip Leak Testing

- Customer Name : - Senior India

Application

- 25 No's Thin tube testing by pressure switch under water

- Pneumatic cylinder Lifting

- Air reserve with air booster

- SS-304 fixture

- Water resistance air cylinder

- Machine Name : - Heat Exchanger Dry Leak Testing

- Customer Name : Senior India Manesar

Application

- Ateq unit for leak testing

- 4 Port sealing by air cylinder

- PP sensor

- HMI Display

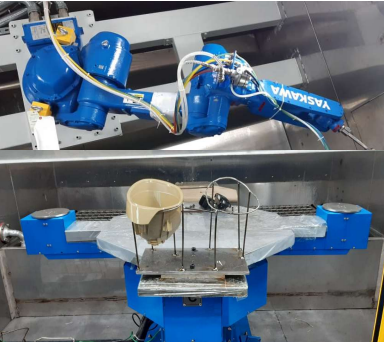

- Machine Name : Robotic Painting System

- Customer Name : Minda Industries Manesar

Application

- Automatic paint with Yaskawa Robot with turn table.

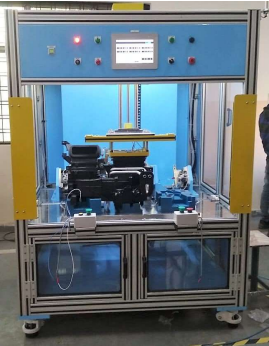

- Machine Name : End of line Testing

- Customer Name : Sanden Vikas Palwal

Application

- End of line testing machine for blower.

- Current voltage measuring at different Knob rotation.

- Knob rotating torque measurement

- Machine Name : Solenoid Testing

- Customer Name : Minda Auto elektrik

Application

- Resistance check

- Pull in Voltage Test

- Contact Drop Test

- Travel Test

- Hi-Voltage Test

- Machine Name : Retrofit convert

- Customer Name : Minda Auto elektrik

Application

We have converted from PC based to PLC based with new feature.

- Panel Changed

- HMI Based

- PLC based Programming

- Machine : Plug Top Assy

- Customer : Lucas TVS

- Product : Ignition Coil

Description

- Primary & Secondary Winding Assy

- Terminal Pressing

- C-Core Assy

- Magnet Dispensing

- Gasket Assy